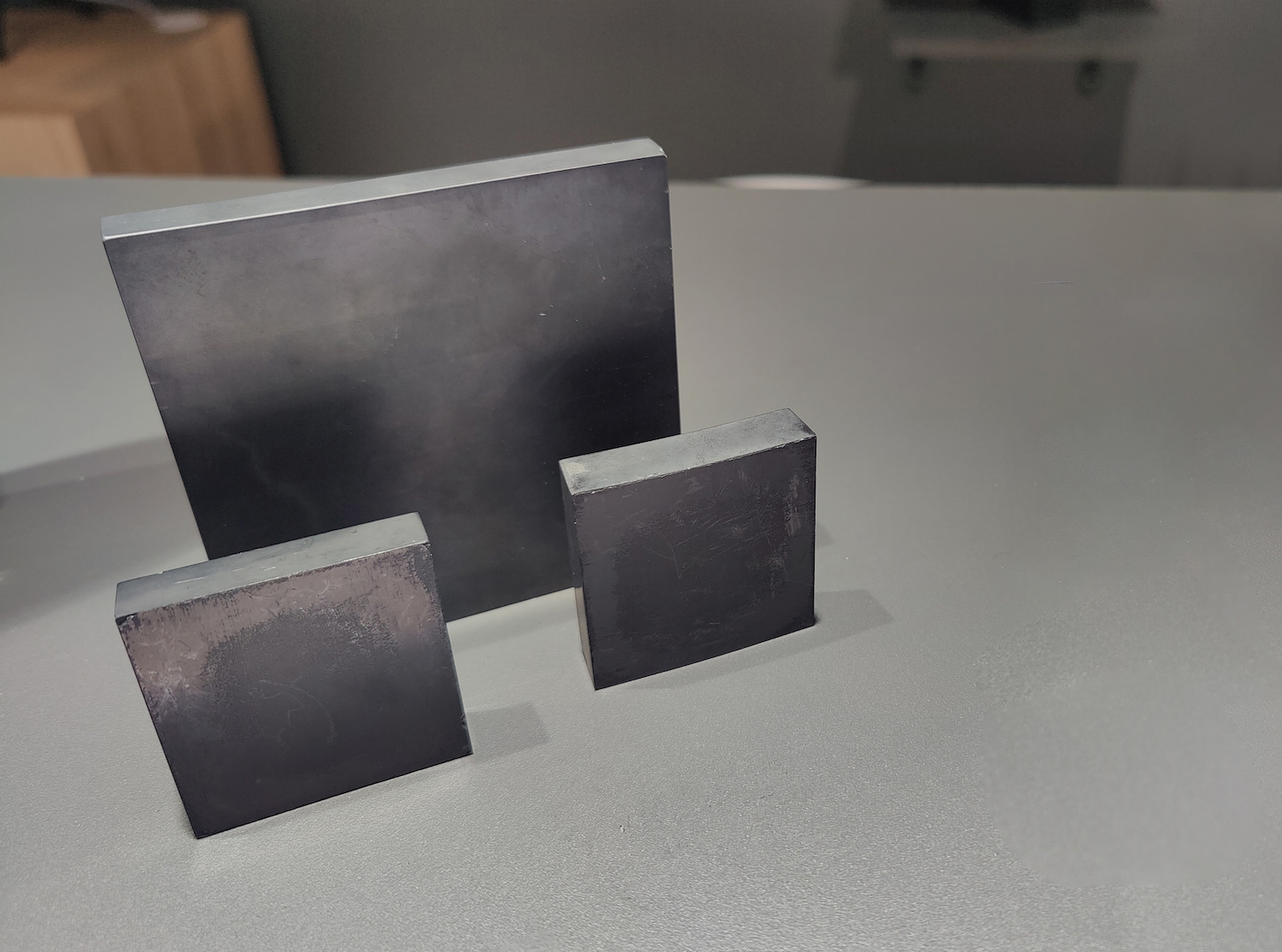

Photo: Shvabe

Under the new production development program, Shvabe holding is setting up manufacturing of ceramic armor plates from sintered silicon carbide (SSiC) for panels that are used in armor vests. Another test stage has been completed and proved high protection class Br5 of the products. These products will improve the combat gear reliability.

Ceramic armor plates are produced by Lytkarino Optical Glass Factory (LZOS), Shvabe holding. They ensure effective absorption and dissipation of the energy from various weapons due the unique manufacturing process.

“Rostec continues its efforts to expand the family of personal protective gear. Under this program, Lytkarino Factory has set up new promising line for production of ceramic armor plates. These products are currently of high demand with the military gear manufacturers. The armor plate manufacturing process uses the unique cold isostatic pressing method improved by our personnel. This allows to achieve a high quality microstructure of the products and stable strength performance. As a result, we get more hard, light-weight and cheap products,” said Bekhan Ozdoev, Industrial Director of the Weapons Cluster of Rostec.

The test has shown that the panels consisting of the ceramic armor plates ensure protection not only against a standard assault riffle shot, but also against SVD sniper rifle bullets, including those with armor-piercing cores.