Capability of taking off and landing almost on any level ground, high maneuverability, functional flexibility – all these features make helicopters indispensable for our country. Delivery of passengers and goods to hard-to-reach locations, medical team operations, geological survey, oil and gas field operations, border control – all this is impossible today without helicopters. Therefore, production of domestically made helicopters and engines for them is of highest priority.

UEC-Klimov as part of United Engine Corporation is the only Russian company that develops and manufactures helicopter engines. The company’s products are successfully used as part of helicopter propulsion units in 80 countries in adverse climatic conditions. It is thanks to Rostec’s St.Petersburg-based company that our country is one of the world leaders in this field producing almost all types of rotorcraft.

Klimov’s engines such as the GTD-350 for the Mi-2, TV2-117 for the Mi-8T, TV3-117 and VK-2500 family engines for the Mi-8MTV (AMT), Mi-171A2, Mi-24, Mi-28, Ka-52 and their modifications, TV7-117V for the Mi-38 and its modifications are a source of pride for the domestic engine building sector.

Another two developments of UEC-Klimov in new sizes – VK-650V and VK-1600V – are coming soon to substitute foreign engines on Ansat, Ka-226T and Ka-62 helicopters. Therefore, with the emergence of these power units, it would be safely said that a complete range of engines for aircraft of all types has been established in Russia.

VK-650V: for light helicopters and more

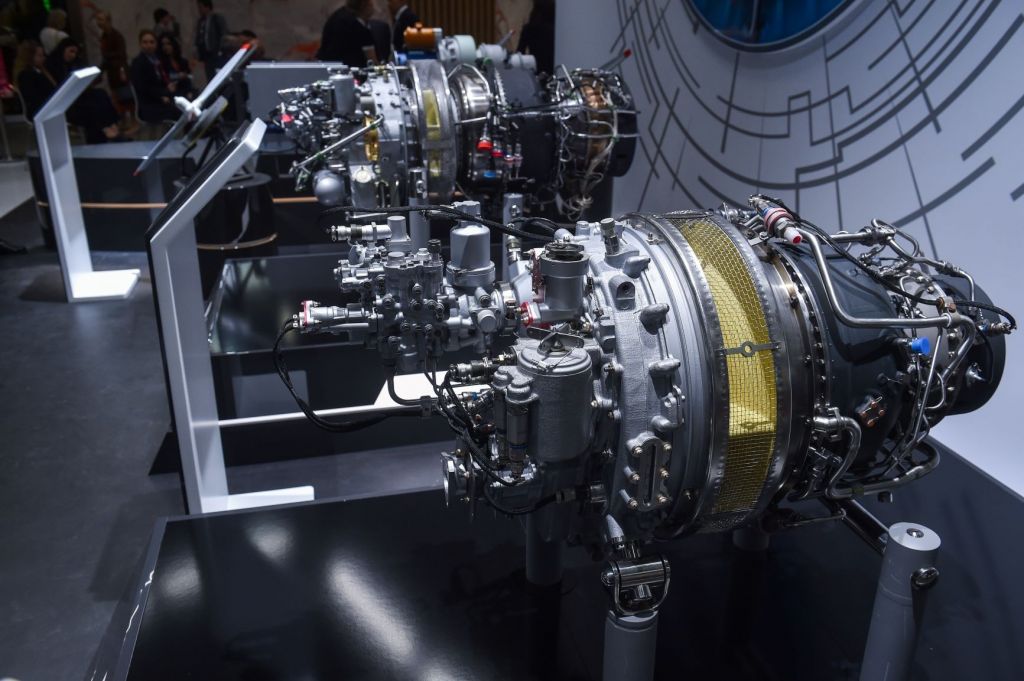

United Engine Corporation is going to produce 10 prototypes of the latest helicopter engine – VK-650V. Four of them will be involved in flight test. The engine has already passed the design engineering test, its structural design and specifications have been defined.

The VK-650V output is 650hp. It is designed for utility and special-purpose helicopters, primarily, for the Ka-226T and Ansat. Moreover, the power unit may also suit foreign helicopters. With minimum modifications, the VK-650V is applicable for unmanned aerial vehicles and for the use as part of a hybrid system combining the benefits of a gas turbine engine and motor. Modular design, good service life, FADEC type computer-managed digital control system are among the engine benefits.

The work on the VK-650V was started in 2018. Within the shortest possible time, the engine demonstrator was created with digital twins and fully additive technology having no small part in this. The work on such scale and in such limited time was ensured by a high level of cooperation.

As for the fully additive technology, of particular note is one of the major achievements of UEC – a welding process for additive components. Their high quality was proved on the engine demonstrator during testing.

VK-1600V: multipurpose prospects

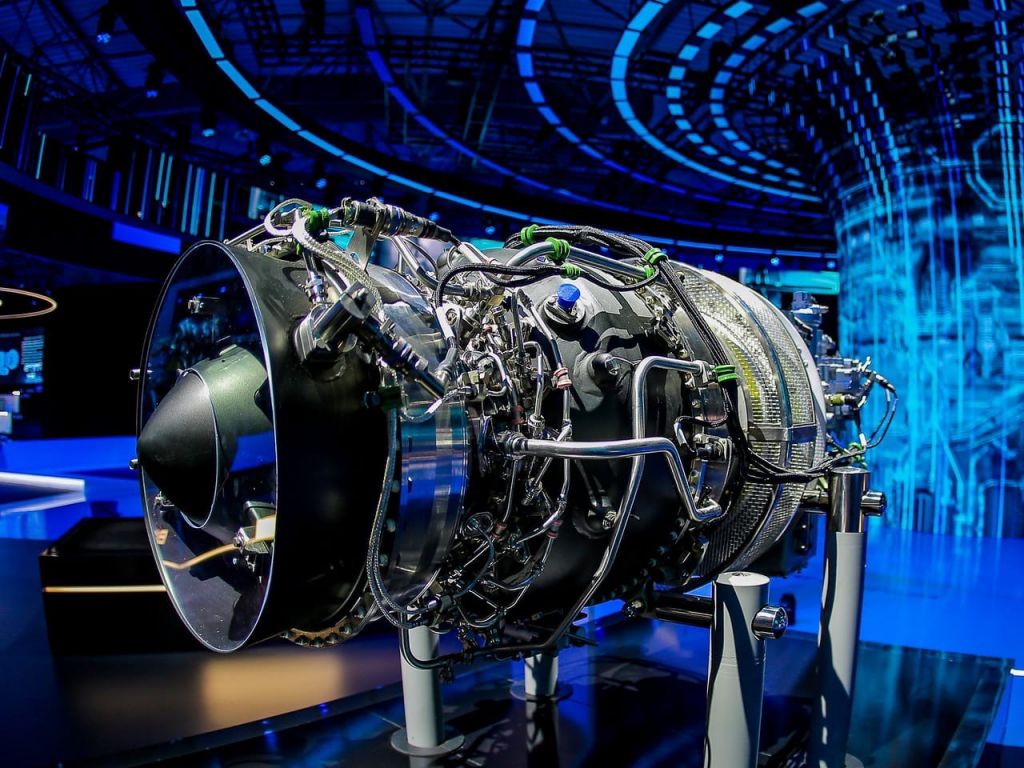

Another recent helicopter news was about completion of the demonstrator test that has been carried out for VK-1600V helicopter engine developed by UEC-Klimov for Ka-62 helicopter and other multipurpose rotorcraft with a take-off weight from 5 to 8 tons. The first prototypes of the product have been already fabricated – their bench test is to be completed by the end of the year and flight test is to be started in 2024.

VK-1600V engines feature high fuel efficiency and low life cycle cost. The takeoff power of the new Klimov’s product is 1400hp and the 2.5-minute power is 1750hp. The propulsion system is operated by BARK-15V control unit also developed by UEC-Klimov.

Similar to VK-650V, digital technologies are extensively used to reduce the lead time of this engine. For the first time in the Russian aircraft building sector, design documentation was initially prepared in the form of annotated 3D models. Using this technology, guaranteed applicability of the models in the system and interfacing control for all engine components are ensured. A lot of components are also manufactured using 3D printing techniques: for the engine demonstrator manufacturing process, additive technologies have replaced about 70% of casting for VK-1600V.

It should be noted that the aircraft engine development cycle in global practice – from an idea to commercial production – is about 10 years. Only five countries, including Russia, possess such technologies. Russia is one of few countries in the world that produces any types of helicopters from scratch and ensures their full life cycle, including helicopter engine production and maintenance.