Since 2009, Rostec’s companies have taken extensive efforts to restore the national machine-tool industry. STAN holding was established in 2012 on the basis of Sterlitamak Machine-Building Plant. Since 2019, the holding has been operated by RT-Capital, Rostec subsidiary, and designs new Russian machines together with RT-Capital. STAN’s structure currently includes NPO Stankostroenie, JSC Stankotekh, Ryazan Machine Tool Works, Ivanovo Machine Tool Works and Grinding Machines.

STAN’s machine family includes three- and five-axis milling, turning and turning-milling CNC machining centers, rotary-type machines, grinding machines, heavy-duty presses and other high-tech equipment. The objective of the holding is to design high quality machines with high local manufacturing content level and competitive prices to cover the needs of Russian manufacturers.

1000VBFL machine: expert in blades

Blade is an essential part of an aircraft engine and requires high-accuracy manufacturing. These are just the kind of specifications possessed by the machines which are supplied by STAN holding for manufacturing gas turbine engine compressor blades. 1000VBFL machine is a holding’s new product that has been already used to manufacture blades for cutting-edge PD-8 and PD-14 aircraft engines.

The machine is a special-purpose five-axis milling machining center designed to manufacture complex parts, certainly including turbine blades. The machine is fitted with state-of-the-art drive systems and Russian-made numerical control system. The machine thus has high accuracy – the allowable positioning accuracy is up to 10µm. This is four times lower than the minimum human hair thickness and is equal to the average spider web thread thickness.

Another feature of the 1000VBFL is its multiple-angle capability. It can machine different sides of a workpiece at different speeds of the integral-motor spindle in which the machining mill is inserted. The integral-motor spindle speed may achieve 20,000 rpm. This enables the designers and process engineers to introduce new engineering solutions even at the design stage and to design complex shaped parts.

STSh EKO machine: robot grinder

STSh EKO robot-assisted CNC machine is another STAN’s new product and the first batch of machines has been already manufactured. It is a kind of machine for machines, because it handles replaceable carbide inserts – cutter elements, cutting tool blades for metal working machines.

The STSh EKO, in turn, is designed to “sharpen the blades”. The machine’s robotic arm grips the workpiece and grinds its faces with a diamond disk. This is the best way to machine an insert made from carbide – wear-resistant metal that maintains its properties even at very high temperatures – up to 1150 °С. Also, the STSh EKO can machine polycrystalline diamond inserts that are used in manufacturing stone and rock working tools.

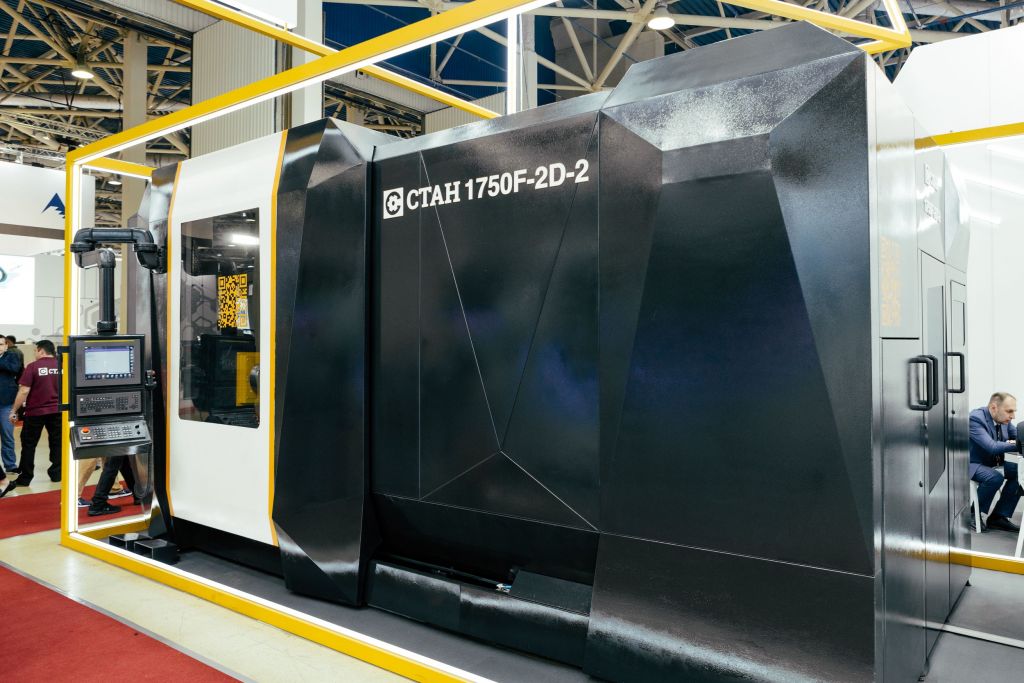

1750F machine: lover of cylindrical shapes

1750F turning-milling machining center is another promising STAN’s product. This center is fitted with a double guiding system to combine heavy and high-speed machining capabilities using roller guides. It is used to manufacture rotation bodies – complex-geometry cylindrical parts – for example, shafts and sleeves often requiring pinpoint accuracy. The machine serves this purpose in all its aspects - it has vibration-resistant base housing parts, advanced guides and thermally symmetrical internals to avoid thermal strains that may occur during manufacturing.

Flexibility is another benefit of the machine. Its tool magazine includes up to 120 cutting tools. Thanks to this and also its design features, the machine can perform multiple process operations for which additional tooling had to be made before. Now, all operations can be made by a single machine which considerably reduces the final product cost.

1750F machine has a modular design. Due to this, it has been used as a basis for a whole machining tool family. It is important to emphasize that this type of machine is fitted with a Russian-made computer numerical control (CNC) system which is immune to external blocking.