IZHMASH is the largest Russian small arms manufacturer, which in 19 and 20 centuries produced every single item of weapon. The factory develops and releases almost the whole range of shoulder arms. Here famous AK-47 manufacturing started. Nowadays the shotgun is employed by 106 countries.

BEGINNING

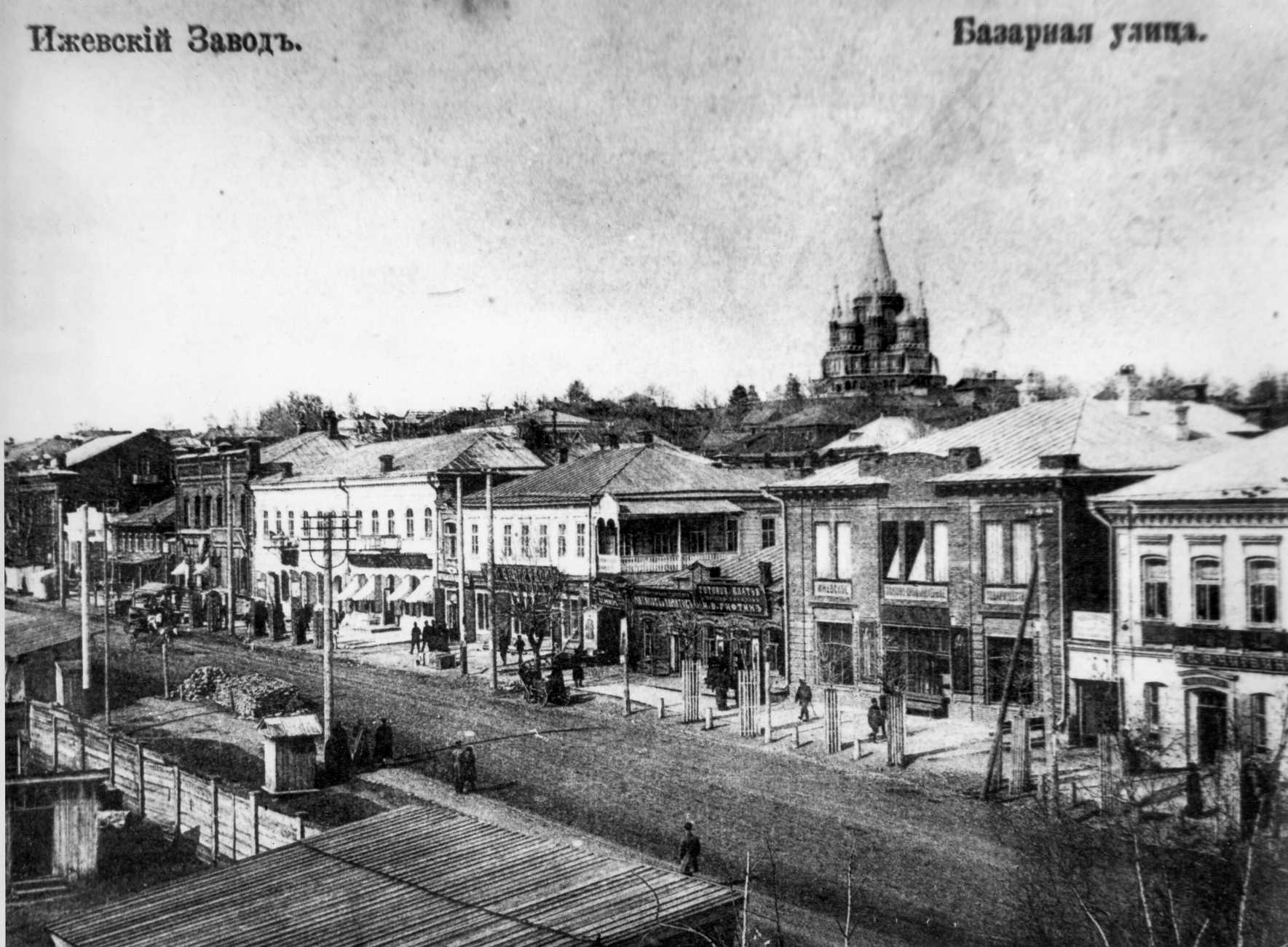

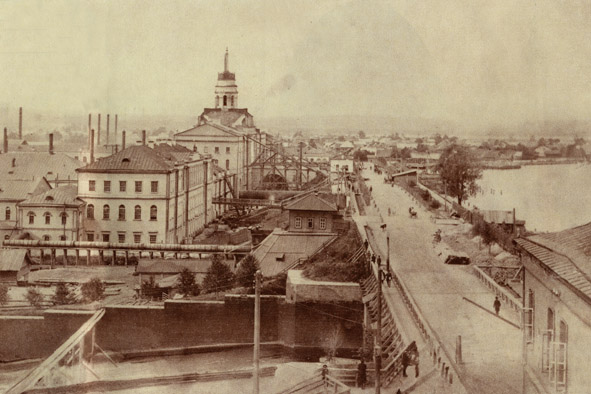

Izhevsk Gun factory construction started in 1807 by the order of emperor Alexandr I (according to some sources, the venture was called Kama-Izhevsk Alexandr Factory). That year more than 2 century history of the world-renowned enterprise started.

Andrey Deryabin, mining engineer, was responsible for the construction and site picking. The place (the bank of the Izh river) was chosen due to the proximity of iron works, which immediately solved all the raw material supply problems.

Now Deryabin is widely known as Izh-town founder, since the factory managing Arms Office opening became a great impulse for the whole town development.

Deryabin employed Russian and Udmurtian ploughmen living in the neighbourhood. At that time ploughmen were to migrate to plants and work there. Far settlements were released from these responsibilities but had to provide works with wagons, horses and harnessing. It also was Deryabin that hired foreign specialists to guide Russian craftsmen.

Ten stone plants, several wooden constructions and a towered main building were erected in 1811-1816.

FIRST WEAPON

First weapons were produced in autumn of 1807. It was the #15 17.7 mm smoothbore muzzle-loaders for soldiers. The plant supplied the Kutuzov Army with over 6 thousand #15s.

Russian smooth-bore 17.7 mm gun made in 1808 was mass produced for infantry equipping. There also were grapeshot-loading ranger, uhlan and horse-guard short rifles, cuirassier and hussar carabines, dragoon musquets, flint blunder buss made in 1809.

The venture also produced pistols and gun parts and remelted trophy weapons.

After a while the plant started producing uhlan, horse-guard, cuirassier and dragoon rifles aside from infantry arms.

In the1830-1840s the works manufactured Gartung short rifles, Phalis breech-loading shoulder-weapons and boarding guns for the Baltic fleet aside from infantry pistols and cuirasses.

In 1844 the decision to upgrade current guns into more rapid firing percussion muskets was made. Cap lock gun production started in 1845.

During the Crimean War, Izhevsk supplied the Army with 130 thousand rifles and a third of them were grooved.

First guns employed by Russian Army were Luttich short rifles for infantry battalions made in 1843.

FIRST 50 YEARS OF THE FACTORY

During the 50 years of the plant’s operations over 670 thousand of flint guns and pistols, over 220 thousand percussion muskets and pistols, over 58 thousand rifle guns and impressive number of cold weapon were produced.

As for the cold steels, the venture manufactured knives with scabbards, cuirassier backswords, dragoon sables, short brown bills and lances. In 1835 the plant decided to transfer cold weapon production to Zlatoust and focus on fire-arms manufacturing.

PUBLIC-PRIVATE-PUBLIC

In 1867 Izhevsk gunsmiths got a kind of manumission and the enterprise was leased to private management. In 1884 the plant was returned to the state and became Izhevsk Gun and Steel Factories (IGSF). Berdan four-port rifle (produced in 1874-1890) was the most popular gun of the plant. It allowed Russia to approach the European industrial empires’ level of armaments.

.jpg)

1885 started manufacturing of hunting weapons. Later, in 1922, the first state hunting gun factory was opened on the enterprise‘s premises.

FIRST WORLD WAR AND AFTER

During the First World War the plant supplied army with over 1.4 million of new rifles and approximately 188 thousand of remelted shoulder wepons. By 1917 the works employed over 34 thousand people.

In the 1920s the venture manufactured various types of civil goods including the railway buffers, acid ammonium molibdate, emery sticks, etc. The town’s chemical industry commenced with the establishment of works for Berezol effective cement power production. In spring, 1925 the plant started manufacturing crankshafts and aircraft engines and first Soviet motorcycles in 1929. In 1930 IGSF organized a machine-building insourcing. In 1933 a motor-plant was founded in Izhevsk and some specialists and equipment from Izhevsk Gun and Steel Factories were transferred there.

Mosin dragoon rifle, produced mainly by the plant, was upgraded in 1930. The three-port Mosin rifle made in 1891/1930 was employed by Russian Army and Navy. The first sniper gun was based on the Mosin rifle and produced in 1931.

The works also designed the aircraft machinegun, aircraft gun and antitank weapon producing technology.

In 1939 Plant № 180 was diversified into metallurgic Plant № 71 and engineering Plant № 74, which also manufactured weapons.

SECOND WORLD WAR

During the Second World War the works released 11.3 million rifles and carabines, which exceeded all the German plants’ output (10.3 million). Over 15 thousand aircraft guns and over 130 thousand antitank weapons were produced. Besides, mass production of antitank weapons, aircraft guns and machineguns, pisotls and revolvers was set up. It took 24 hours for the works to supply one rifle and one air divisions.

In 1941 the plant set up Degtyarev antitank gun production less, than in a month. Simonov antitank gun was ordered in November, 1941 and already released in 1942. Berezin aircraft machineguns (UB-12.7) production was mastered in a short term, TT pistol and Nagant revolver production was aligned. In 1942 manufacturing of 37 mm Shpitalny and Nudelman-Suranov NS-37 aircraft guns and sniper rifles with optic sights commenced.

On July, 20 1942 Plant № 622 (future Izhevsk Mechanical Plant) was segregated from Plant № 74. Part of the equipment was transferred from Izhevsk Engineering works, a part was obtained at evacuated Tula and Podolsk mechanical plants. During the war, Plant № 622 produced Degtyarev-Simonov antitank guns, TT pistols, Nagant revolvers, flare guns, ignition case primers.

AFTER WAR

During the postwar period the plant started to release a wide range of civil goods like agricultural equipment, furniture and other. At the end of the 40s main civil products were hunting weapons. In 1945 Izh motorbikes manufacturing was resumed.

At the end of the 50s the plant was involved in cosmic exploration and created first S-325-B launch vehicle for the Earth atmosphere scanning and gaining data on near space characteristics. At the beginning of the 70s M-100B and M-120 were designed, vacuum devices (magnetrons) for modern aircraft and missile early detection systems were produced.

Sporting variants of hunting guns were designed. TSSV-1 and S-49 target sporting rifles, TSV-50 and MTSV-50 free rifles for 7.62 and 5.6 mm cartridges were produced. Evgeniy Dragunov commenced and headed upgrading the target rifles in 1955.

Hunting models were also being improved. In 1960 the Bars rifle appeared, in 1961 Madved was constructed and in 1964 Los was released.

The development of sniper weapons continued. Dragunov headed 1891/1930 sniper rifle improvement in 1948 and created new model, MS-74. Testing showed advantages of the gun to Simonov rifle. 7.62 mm Kalashnikov assault rifle was also designed in 1948 and mass produced in 1949. On July, 3 1963 7.62 mm Dragunov self-loading sniper rifle was employed by the Soviet Army.

In 1942-1952 the plant’s design bureau had a team of 16 German gunsmiths-designers including Hugo Schmeisser, the inventor of StG 44, Gustlof Werke, chief designer Karl Bartnicke and his assistant Oskar Schink, Werner Gruner and Kurt Horn, the developers of MG42.

In 1975 Izhevsk engineering plant became IZHMASH Industrial Association.

In 1984 the plant started production of artillery shells (Krasnopol, Kitolov, etc.)

In 1993 Viktor Kalashnikov and Aleksey Dragunov developed PP-19 Bizon submachine weapon. In 1994 Russian Army employed AN-94 Abakan Nikonov automatic rifle produced by IZHMASH.

Hunting carabines based on Kalashnikov’s Saiga were gaining wide popularity. The series development started with Saiga for 7.62х39 cartridges release in 1992. Later other weapons of the series appeared (Sobol, Tigr, Los, Volk).

IZHMASH expanded its production and commenced manufacturing the GP-34 grenade launcher and UAV.

NOWADAYS

After the plant was amalgamated by Rostekhnologii State Corporation in 2008 IZHMASH became a parent company of the close combat weapon systems’ holding. The holding ventures produce ammunition, high-precise weapon, UAV, automatic small arms including automatic guns, submachine weapons, pistols, shooting-grenade launchers and sniper weapons, develop technologies and manufacture special equipment for production.